Conversion of Micro-Trains 50' gondola

Some of Micro-Trains' gondolas are built up like this: A cast metal underframe on which trucks with couplers are mounted, and an injection-moulded plastic body is snapped onto the underframe. The cars are delivered with wheel sets with high "pizza cutter" flanges and truck-mounted couplers. With newer cars Micro-Trains has put a set of "low profile" wheel sets into the box.

The cars are designed so that the height from rail top to mounting platform is 7.4mm. There are two holes in each end of the underframe that fit the Micro-Trains #1027 couplers. I don't like the #1027 coupler as the coupler spring is in compression when the car is hauled, this can lead to the cars bouncing back and forth in a long train. Furthermore, the cars are sitting a little high on the trucks, probably because of the large flanges used.

I like to use wheel sets with small flanges and #1015 couplers. This type of coupler is designed to be used with a shim for a mounting platform height of 7.4mm above rail top and 7.1mm without a shim. I take advantage of this difference by filing off around 0.3mm from the truck bearing surfaces on the underframe bolsters so that the #1015 couplers can be used without shims.

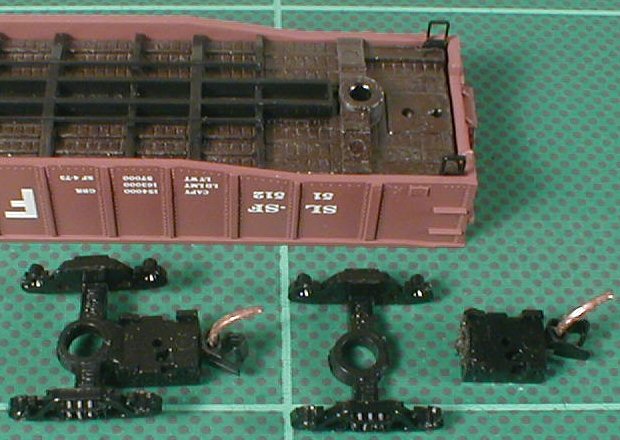

Photo 1: Here the car is seen as delivered with "pizza cutter" wheel sets and truck-mounted couplers. The truck bolster pin is pressed into a hole in the underframe bolster.

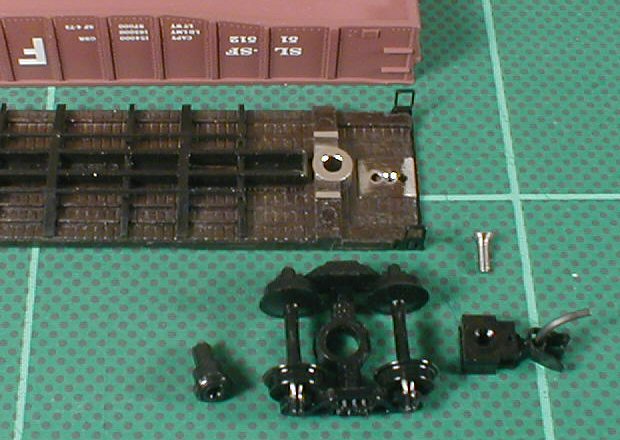

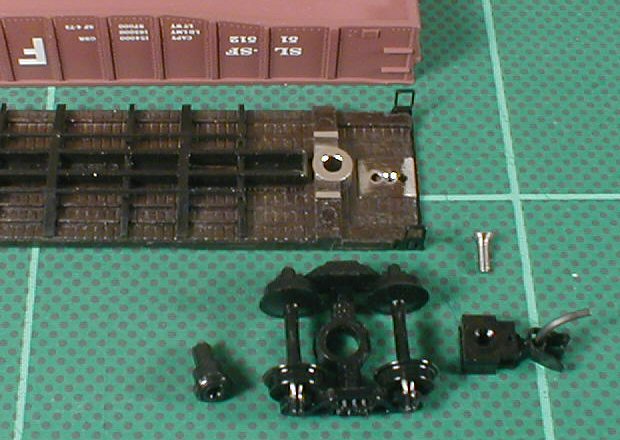

Photo 2: The trucks are removed from the underframe by pushing out the bolster pins, and the wheel sets are removed. On one truck the coupler is cut off using a jeweler's saw and cleaned up with a sharp knife. Be careful that enough material remains around the truck bolster hole.

Photo 3: The underframe is removed by prying up in one end using a small screw driver. The truck bearing surfaces are filed down and new mounting holes for the couplers are drilled and threaded using a M1.2 tap. New "low-profile" wheel sets are mounted in the trucks; a bolster pin is seen to the left. An assembled Micro-Trains #1015 coupler and M1.2x4 countersunk mounting screw are seen to the right. This screw type fits this installation well but the screws will have to be longer if shims are used or the underframe is plastic.

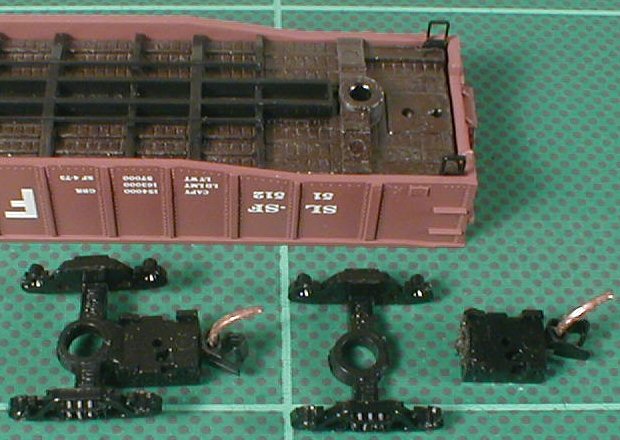

Photo 4: The new #1015 couplers are mounted and the trucks and underframe are remounted after the changes have been made.

Figure 1: I have devised a little gadget to file underframes as shown here. I fix two blocks to a hardwood base, the blocks are preferably of brass or wood with brass shims glued on top (more layers may be glued together to fit). The height corresponds to the finished thickness h of

the underframe bolster and the distance between them is just a little more than the width of the underframe. The underframe is secured with one or two wood screws. I then file off the bolster surface until the file touches the two blocks.

Updated 2011-07-15