Conversion of Micro-Trains 39' tank car

Micro-Trains' 39' tank cars are built entirely from plastic, also the underframe which is rather delicate. The cars are delivered with wheel sets with high "pizza cutter" flanges and truck-mounted couplers. With newer cars Micro-Trains has put a set of "low profile" wheel sets into the box. The cars are designed so that the height from rail top to mounting platform is 7.4mm. There are two holes in each end of the underframe that fit Micro-Trains #1027 couplers.

This coupler type is relatively easy to install on the car. I do, however, not like the #1027 coupler as the coupler spring is in compression when the car is hauled, this can lead to the cars bouncing back and forth in a long train. Furthermore, the couplers are drooping as the underframe is distorted when the coupler box is fixed using a screw.

I like to use wheel sets with small flanges and #1015 couplers. This type of coupler is designed to be used with a shim for a mounting platform height of 7.4mm above rail top and 7.1mm without a shim. It is not possible to tighten the screw sufficiently to fasten the coupler box when screwed into the plastic underframe. That's why I have made special shims from 0.3mm brass sheet that is glued to the underframe, and a thread is cut into each.

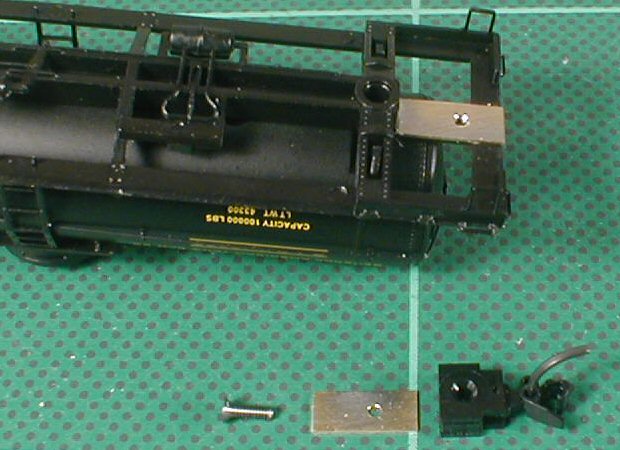

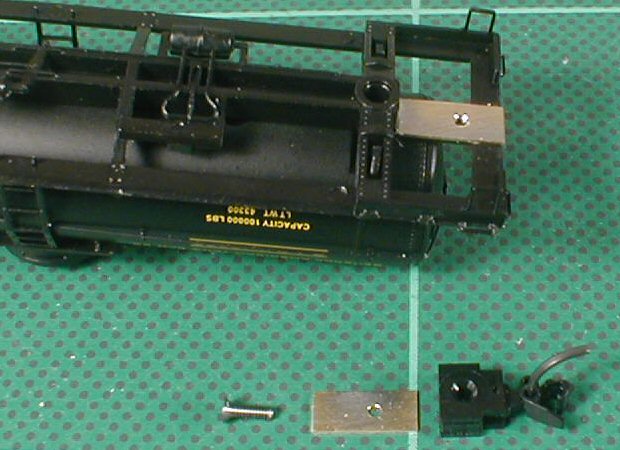

Photo 1: The tank car with the original truck-mounted couplers; the wheel sets have already been changed to "low profile" wheel sets.

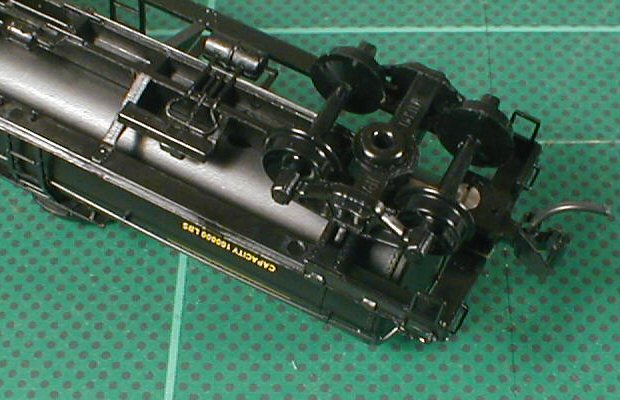

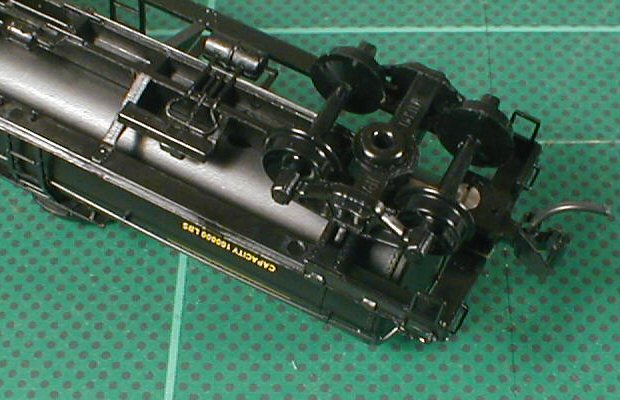

Photo 2: The trucks are removed from the underframe by prying out the bolster pins, on the right truck the coupler is cut off using a jeweler's saw and cleaned up with a sharp knife.

Photo 3: The wheel sets are remounted in the truck; to the left is seen a bolster pin that is a press fit into a hole in the underframe bolster. Threads are cut into the foremost coupler mounting holes for #1027 couplers. To the right is (upper) an assembled #1027 coupler and a 00-90 screw and (lower) an assembled #1015 coupler.

Photo 4: Trucks and #1027 couplers are mounted; the screws are shortened to a length of 4mm.

Photo 5: The car with #1027 couplers; the drooping of the coupler is clearly seen.

Photo 6: A shim 3.6x8.4mm from 0.3mm brass sheet with a 1mm hole 3.5mm from the end of the underframe is glued on using epoxy. The hole is drilled through and a M1.2 thread is cut into it. Below can be seen a M1.2x4 countersunk screw, a shim and a #1015 coupler.

Photo 7: The #1015 couplers and the trucks are mounted.

Photo 8: These couplers do not droop. The only thing missing is a little paint to hide the shining metal surfaces of the shims and screws - and the weathering, but that is entirely another issue.

Updated 2009-01-04